Automation by Design

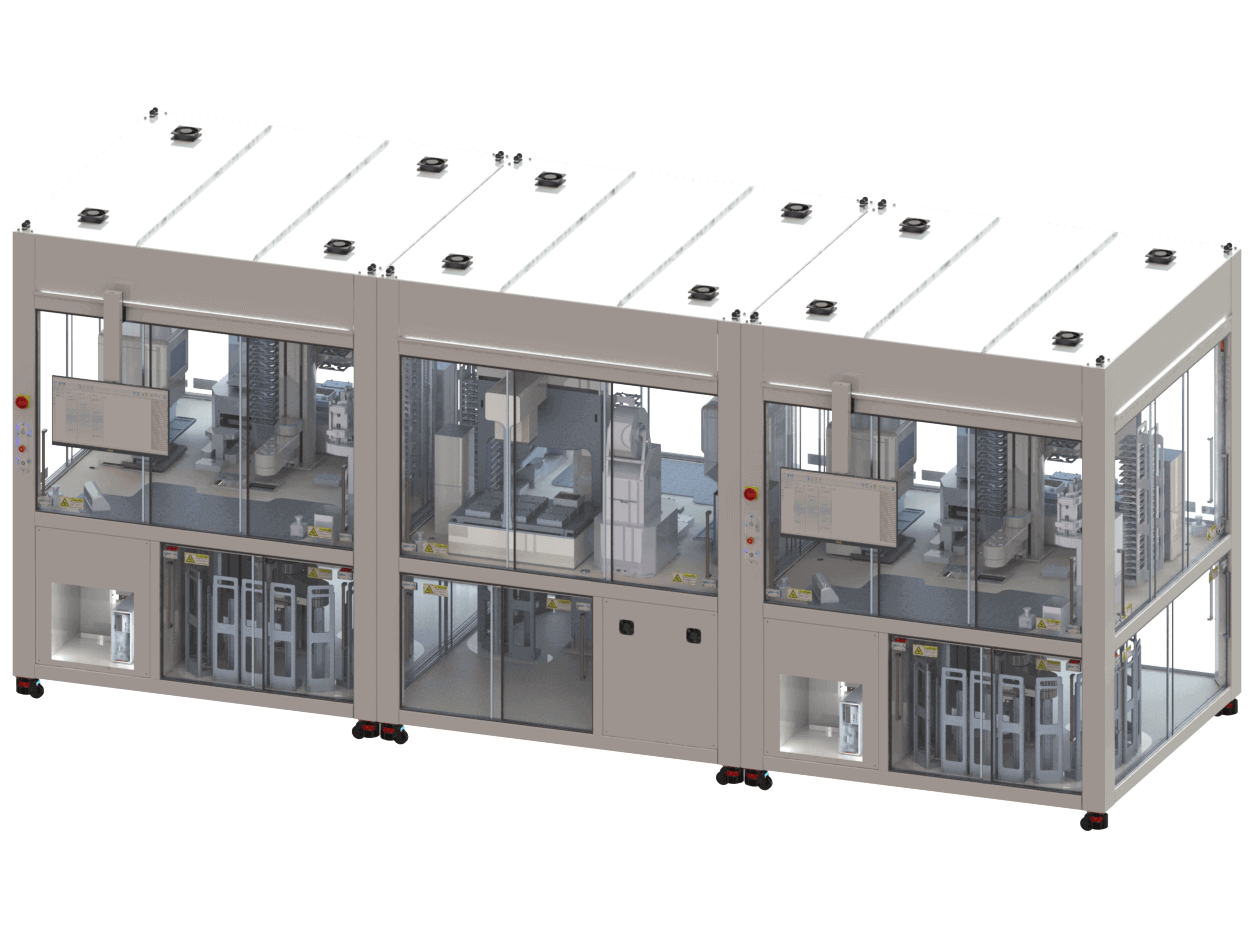

Providing you with a solution that encompasses your needs while remaining future focused and mindful of your changing needs.

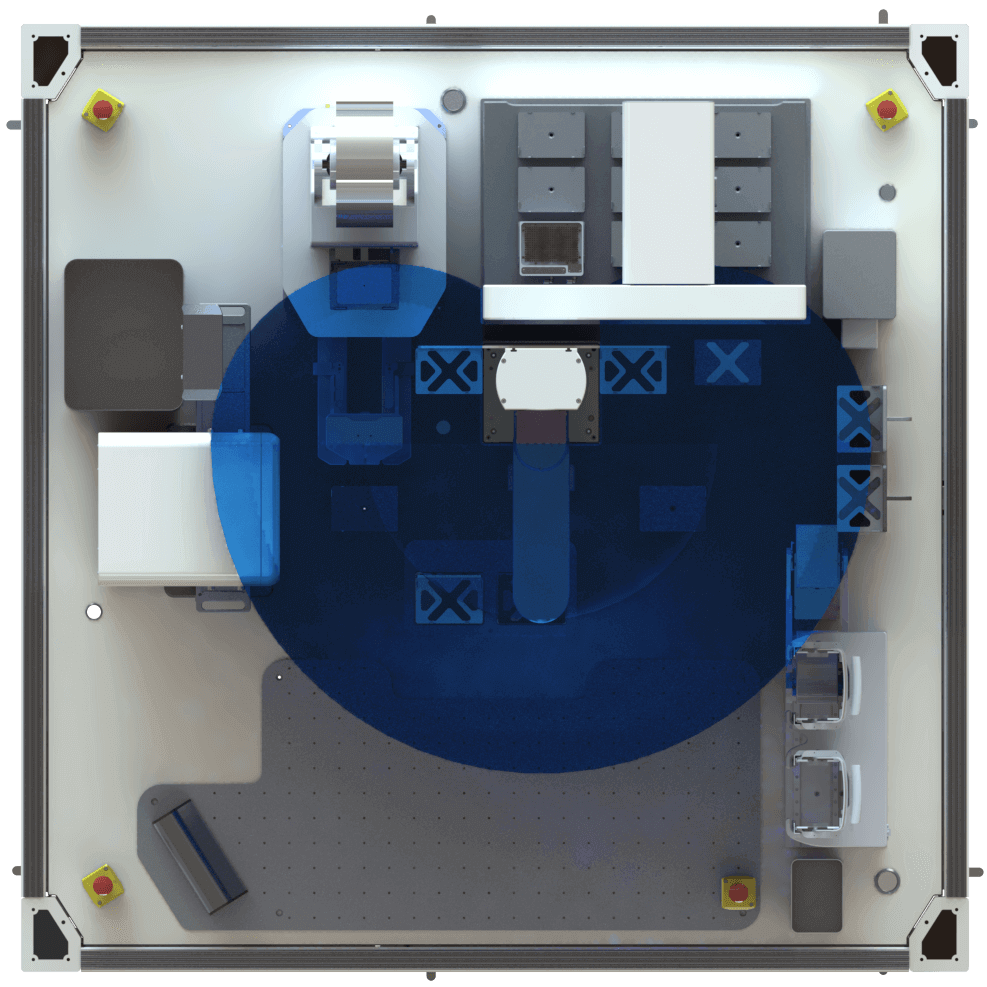

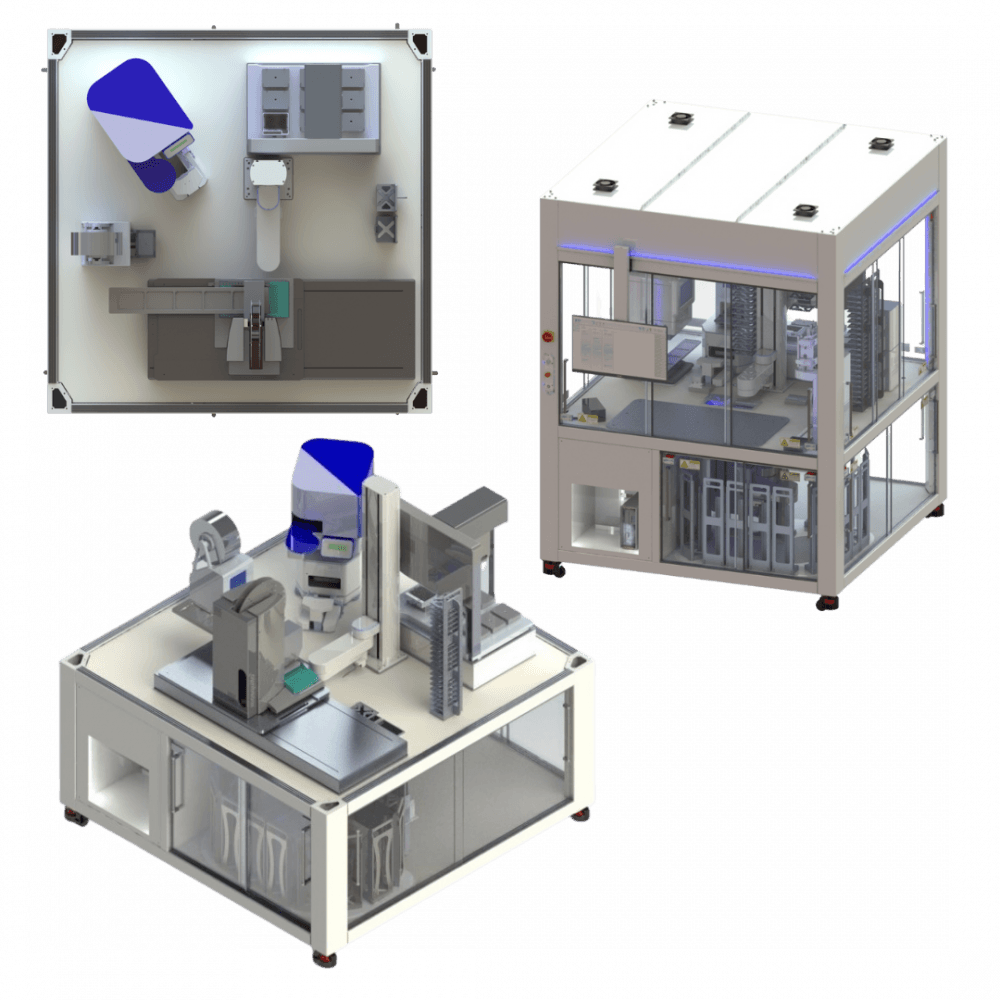

We use our extensive experience to scope and develop the exacting solution for your requirements, with provision for future expansion or adaption. Our design specifications include layout plans for the system in your laboratory, encompassing any access or space restrictions that need consideration.

We combine our technical expertise with the power of automation to create one individually bespoke and fully integrated system that boosts throughput processes in your laboratory, whilst simultaneously creating more insightful and invaluable data.